Materio3D Story - MakerBox

Materio3D Story - Makerbox

After creating our EcoSeries product line consisting of 16 colours of PLA 3D850, testing it extensively and upgrading our extrusion line several times, we were ready to enter the US market. We were trying to find a good way to do just that and we found that sending a bunch of filament to strangers was the perfect way to go.

We reached out to Matthew Gorton at Printed Solid to see if we could be part of a Makerbox package and he told us we can send out our filament in October. We decided on the Dragon Red as it is a bright and popular colour. However, we also wanted to make something special that no one has ever made before.

Being inspired by the painter colour palette, the decision was quickly made that we will print a sample chip of every colour that we have for each box that will ship out. After a quick conversation with Matt, we calculated that 13 000 tags need to be printed in the span of roughly 4 weeks.

4 weeks = 672 hours, one successful 7-hour print yields ~40 tags, so every hour we have 5.7 tags. 1 printer running for 672 hours yields a maximum of 3840 tags, if there are no mistakes and the prints start themselves, which we all know does not happen.

We quickly realized that the printers we have will not be enough to print all those tags, so we reached out to Voxel Factory to see if they could lend their printers for the project. Not only did they get all their printers to print the colour tags, but they even got Will-de-Tek (Voxel’s Technician, real name’s William Puchot) to use his army of printers in his man cave to lend a hand.

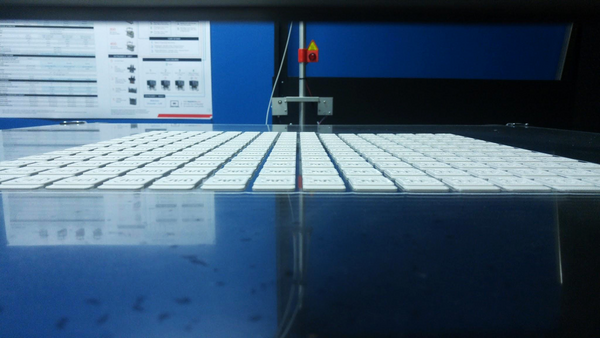

So, for 4 weeks there was constant printing, counting and trying to figure out how to be more productive and smart about our printing. Will-de-Tek had to cut an hour of his sleep each day to make sure his printers were running 24/7. Voxel Factory even put their Workbench Classic by 3D Platform to print over 250 of good quality tags in one go.

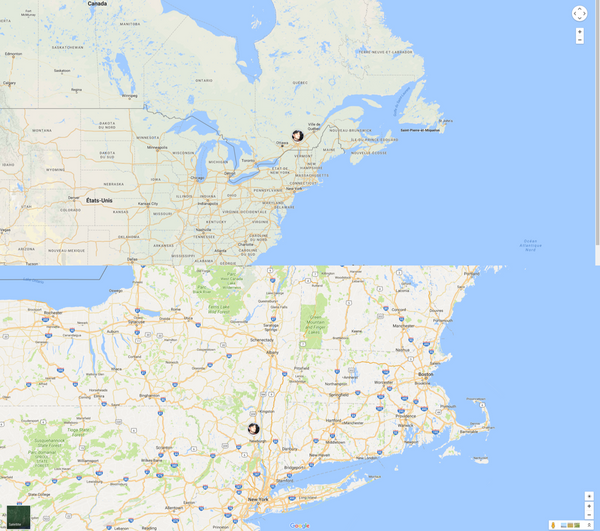

Now, printing is one thing, but we also need to assemble the tags and ship them out a few days, so they arrive before October 20th 09:00. As the deadline approached, we realized that we will need every single hour we can use, meaning the shipping through the border is not going to happen.

Somehow, we were able to print all the necessary tags, all 13 000 of them, on October 19th. We still needed to assemble the tags to make a colour palette. We would like to give a special thanks to Matt Gorton for the wisest of tips ever given: “Make sure you make yourselves some jigs.” Without exaggerating, that saved us hours of assembly.

On October 19th, at 16:00 we started assembling the tags at Voxel Factory, which had a meetup planned on that day at 17:00, but that didn’t stop them from getting things done. Also, one brave soul who showed up for the meetup started helping us. A big Thank-you to Marcel for the genuine help, it is very appreciated.

A few hours later, we managed to have all the tags assembled and ready to go. The clock is nearing 22:00 and the package needs to be delivered by 09:00 the following day. I doubt any shipping company would be able to accomplish such a task. Luckily, François took it upon himself to personally drive all the way from Montreal to Newark, Delaware to deliver the hundreds of colour palettes.

We want to give out a special thank you to all those who participated in this project. Matt Gorton’s team at Printed Solid and MakerBox for the advice & coordination, Voxel Factory’s team for printing & assembling, Julie, Guy and Marcel for helping out with assembly.

Materio3D PLA is now available for purchase at Printed Solid in both 1.75 mm and 2.85 mm!

______________________Printers used for this project: Ultimaker 3 extended, Ultimaker 2+ with Olsson Ruby, Ultimaker 2 GO, Ultimaker Original, Prusa i3 MK2S with Olsson Ruby, Prusa i3 MK2S (Dyze Design upgrade), Prusa i3 MK2 with octoprint upgrade, standard Prusa i3 MK2S, Workbench Classic by 3D Platform, Airwolf3D’s Axiom Dual Direct Drive, BCN3D Sigma R16, Makerbot replicator 2, Ultibot d300vs & Folgertech ft-5.